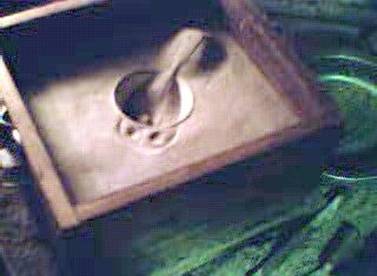

This casting is a symbol of achievement and excellence in the foundry industry. This test of molding skill originated many years ago in the British Isles. Foundrymen there considered molding an art. An apprentice had to spend many years learning and practicing the trade before becoming a Journeyman.

Copyright 2019 Lost & Foundry